Mandatory documents and records required by ISO 90012015. Please note that some of the documents will not be mandatory if the company does not perform relevant processes.

Iso 9001 Processes Procedures And Work Instructions 9000 Store

ISO 90012015 Forms and Templates ISO 9001 Canada.

. Recognized And Prize-Winning Courses Provided Online And For Free - Since 2007. The FAI is typically completed in a purchase order contract. Upon receipt the receiving bay personnel will verify the units delivered and make sure the packages are identified.

Any non-conformances are documented using the Defective Part Report and processed accordingly. Most verifications and validations are integrated into design manufacturing or service delivery processes and are performed by operators inspectors technicians engineers or those performing the service. Here are the documents you need to produce if you want to be compliant with ISO 90012015.

ISO Receiving Inspection Responsibilities. In any circumstance we must order parts from a non-franchised distributor like a broker we will send samples out for testing at an fully certified lab. Inspection receiving iso procedure 9001 procedures bizmanualz audit training policies lean.

It must be stressed that according to ISO 90012015 clause 753 Control of documented information requirements documents may be in any form or type of medium and the definition of document in ISO 90002015 clause 385 gives the following examples. Our Quality Management System documentation is designed to meet the requirements of ISO 90012015 as well as ATEXIECEX certification and to be appropriate to our organizations size and type. We also will do receiving inspections on any brokers on regular intervals and for the first 3 shipments from any new supplier broker or not.

Once the raw material is received it goes through an inspection process and is then checked against the shipping and order slip. Loeb will perform the FAI to ensure that the production process reliably produces what is intended and that the product. Find them all on the ANSI Webstore.

Usually it will proceed as follows. This procedure applies to receipt of all incoming items. The ISO 9001 uses the words verification and validation many times.

In accordance with ISO 90012015. Achieve ISO 9001 The Ultimate Global Benchmark for Quality Management. Ad Learn How ISO 90012015 Offers A Framework For Organizations To Maintain QMS.

ISO 90012015 Annex A. Both the customer and H. Regarding ISO 90012008 clause 743 verification of purchased product requirements its important to remember the primary purpose of conducting a.

DescriptionForm 001 Procedure TemplateForm 002 Incoming Material Receiving LogForm 003 Product Quality Assessment FormForm 004 Internal Audit Plan TemplateForm 005 Internal Audit Summary Report TemplateForm 006 Quality Audit Checklist TemplateForm 007 ISO. When you establish these criteria you will also establish compatible inspection and test criteria. All in-process inspections are recorded using the In-process Inspection Log.

First Article Inspection FAI. The purchasing process is where you put controls in place to make sure that your suppliers provide you with quality products and services. 4 Types Of Inspections For ISO 9001 1.

IMSM Makes ISO Certification Simple. Receiving inspections tie in very closely with purchasing. Ad Fixed Fee Flexible Approach.

Ad Browse Discover Thousands of Book Titles for Less. In accordance with ISO 90012015. The Quality Manager determines the extent and scope of in-process inspection and testing based on the importance of the item control methods and previous performance.

Verification methods include inspection. The primary inspection will be executed in the receiving section. Ad International Standard 2015 version.

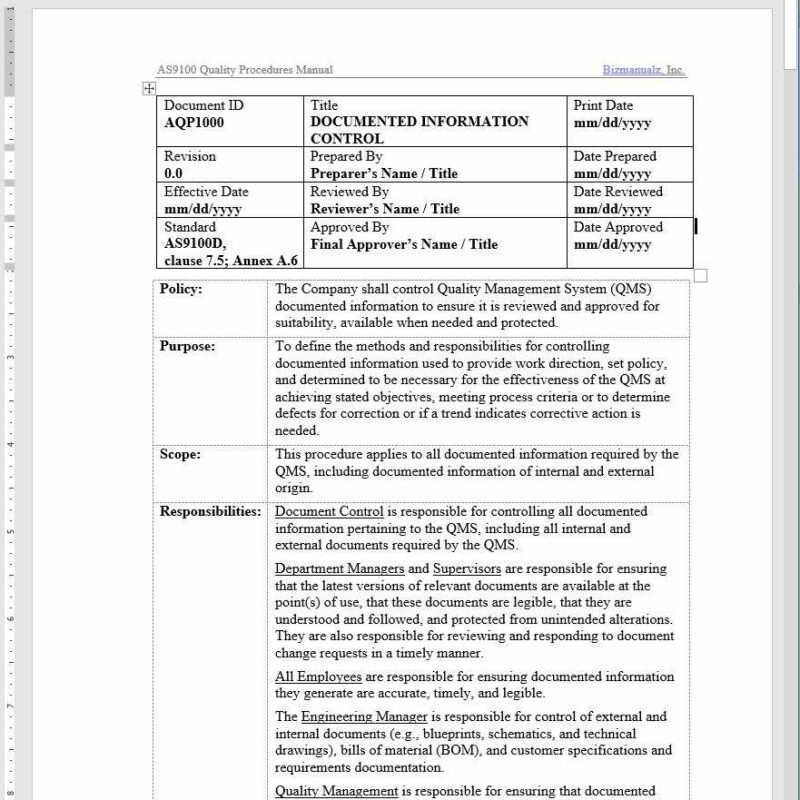

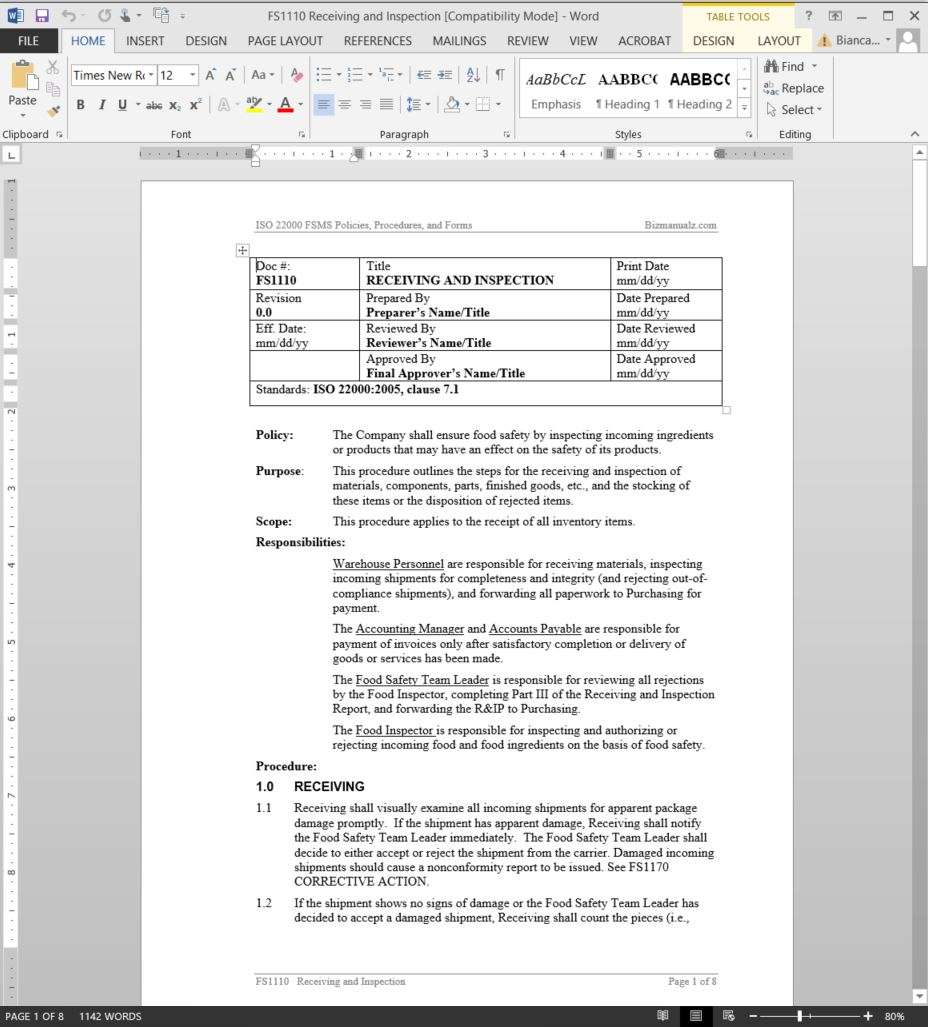

About what is ISO 90012015The ISO Receiving Inspection Procedure describes the process of receiving materials components parts finished goods etc inspecting them when required and determining their disposition. Of the PDCA model. This procedure applies to receipt of all incoming items.

Unfortunately corrections on the ISO 134852003 took The ISO Receiving Inspection Procedure describes the process of receiving materials components parts finished goods etc inspecting them when required and determining their disposition. It does not preclude the use of other quality systems that are compatible with the objectives of ISO 90012015ATEXIECEX and provides equivalent results. Check all boxes or packages for any signs of damage or tampering.

Scope of the QMS clause 43 Quality policy clause 52 Quality objectives clause 62.

Receiving Inspection Procedure Iso 9001 2015

Internal Audit Report Template Iso 9001 2 Professional Templates Internal Audit Report Template Good Essay

Internal Audit Report Template Iso 9001 2 Professional Templates Internal Audit Report Template Good Essay

Manufacturing Control Procedure Iso 9001 2015

Purchasing Procedure Iso 9001 2015 Iso Procurement Procedure

Receiving Inspection Procedure Iso 9001 2015

0 comments

Post a Comment